View the WEDI entry on BPindex

As a certified EcoProfit operation for over 15 years, wedi’s mission is to support the industry improve its carbon credentials and to help consumers recognise the added value of having a ‘green’ home with low energy bills.

Manufactured with at least 25% recycled foam material and 100% renewable energy, wedi XPS products have their own Environmental Product Declarations (EPDs) confirming their environmental footprint throughout their lifecycle making sustainable bathroom construction all the more easier. Lightweight by nature and 100% waterproof to the core, the versatility of wedi’s modular XPS elements allows for enormous freedom in design whilst also offer unrivalled system safety.

Established in the 1980s, wedi as the pioneer of the XPS industry developed many ingenious product innovations that revolutionised the construction industry. wedi is the only XPS manufacturing company whose products received the European Technical Approval (ETA) for sealing of floors & walls in wet rooms. Besides being fixed to existing walls as a levelling, directly tileable tanking solution, wedi building boards from 50mm thickness can also be used to build free-standing partitions. Thanks to their vertical weight loading capability of 133kgs/m2 they are strong enough to support shower doors, radiators, shelves or tray elements in conjunction with the wedi fixings set/reinforcement plates.

What’s more, always at the cutting edge of innovation, wedi also offers ready-to-use partitions. The wedi Sanwell Wall with integrated niche is a robust, 100mm thick partition wall available in 900 or 1200mm widths. The new wedi Sanwell shower wall module however, is just being introduced to the market. It features factory-integrated and sealed water pipes and a Hansgrohe iBox to suit 200+ thermostatic mixer designs and can be used as a fixed wall or as a free-standing partition. What’s more, there are many individualisation options to meet customer specific needs such as an integrated niche or selectable height of integrated reinforcements for the attachment of the shower heads for example. Why spend 4 – 6 hours when a fully functional and versatile partition can be erected within 30 minutes?

What’s more, always at the cutting edge of innovation, wedi also offers ready-to-use partitions. The wedi Sanwell Wall with integrated niche is a robust, 100mm thick partition wall available in 900 or 1200mm widths. The new wedi Sanwell shower wall module however, is just being introduced to the market. It features factory-integrated and sealed water pipes and a Hansgrohe iBox to suit 200+ thermostatic mixer designs and can be used as a fixed wall or as a free-standing partition. What’s more, there are many individualisation options to meet customer specific needs such as an integrated niche or selectable height of integrated reinforcements for the attachment of the shower heads for example. Why spend 4 – 6 hours when a fully functional and versatile partition can be erected within 30 minutes?

wedi’s directly tileable solutions do not only cut back on labour and dust improving health and safety conditions on site, but also reduce interactions between different trades and hence minimise risks and accelerate project completion.

Thanks to their excellent thermal properties (0.036W/mK), wedi building boards are also much sought-after as added insulation beneath underfloor heating systems of all kinds. Underfloor heating is superior to traditional heating systems in many aspects: UFH doesn’t only have a longer lifespan and provide better air flow whilst generating less airborne dust, but is also much more energy efficient. Beyond question however, the response time of underfloor heating systems is slower than that of traditional radiators and their installation is known to be trickier. wedi building boards underneath UFH prevent heat-escape bouncing heat back into the room and hence improve the response time of heating systems by up to a staggering 70%!

Thanks to their excellent thermal properties (0.036W/mK), wedi building boards are also much sought-after as added insulation beneath underfloor heating systems of all kinds. Underfloor heating is superior to traditional heating systems in many aspects: UFH doesn’t only have a longer lifespan and provide better air flow whilst generating less airborne dust, but is also much more energy efficient. Beyond question however, the response time of underfloor heating systems is slower than that of traditional radiators and their installation is known to be trickier. wedi building boards underneath UFH prevent heat-escape bouncing heat back into the room and hence improve the response time of heating systems by up to a staggering 70%!

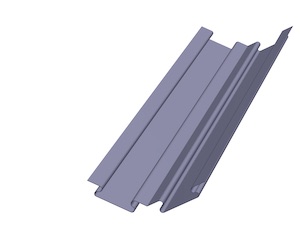

What’s more, in order to help home owners and developers make the right choice for the long run, wedi has developed a building board with integrated grooves for easy installation of hot-water underfloor heating making the installation all the more easier. The wedi PreLine building board is available in 30/40/50/60mm thickness to suit – water pipes are simply laid in the integrated recesses and backfilled using flexible cement based tile adhesive. Through the adaptation of innovation, there is a huge potential for improvement in the speed of construction and the environmental performance of buildings, during and after construction.

wedi’s expertise has recently been called upon a wellness facility operating in a listed building. Built in the 1910s in Art Nouveau style, Neptunbad in Cologne, Germany had been operating as a thermal bath in the 20th century before being transformed into a wellness facility. Several decades on, the much needed renovation was given a green light. The construction had to be able to withstand the long-term high humidity load without drilling into the listed vaulted ceiling of the historic sauna and bathing area meaning that the mounting of the suspended ceiling and the load removal of the utilities on it had to be done entirely over the wall surfaces. Thanks to the integrated support points designed into the wall elements only a simple plug-in connection was needed for the connection of the suspended ceiling structure.

wedi’s expertise has recently been called upon a wellness facility operating in a listed building. Built in the 1910s in Art Nouveau style, Neptunbad in Cologne, Germany had been operating as a thermal bath in the 20th century before being transformed into a wellness facility. Several decades on, the much needed renovation was given a green light. The construction had to be able to withstand the long-term high humidity load without drilling into the listed vaulted ceiling of the historic sauna and bathing area meaning that the mounting of the suspended ceiling and the load removal of the utilities on it had to be done entirely over the wall surfaces. Thanks to the integrated support points designed into the wall elements only a simple plug-in connection was needed for the connection of the suspended ceiling structure.

High degree of prefabrication can save enormous amount of time on the construction site whilst due to the reduction of interfaces between different trades, achieves the highest level of system security providing peace of mind for both the contractor and the client.

Do you have a project to discuss? Please do not hesitate to get in touch, the wedi technical helpline is available during business hours Monday to Friday on 0161 864 2336 or email enquiries@wedi.co.uk