View the Alumasc Water Management Solutions entry on BPindex

Visit the Alumasc Water Management Solutions website

The introduction of the new Building Safety Act in April 2022 was cited by the government as the biggest transformation in how tall structures are designed, constructed and managed, in almost 40 years.

The introduction of the new Building Safety Act in April 2022 was cited by the government as the biggest transformation in how tall structures are designed, constructed and managed, in almost 40 years.

The Act enforces compliance to Building Regulations restricting the use of combustible materials in the external walls and specified attachments for residential blocks of flats, student accommodations, care homes, sheltered housing, hospitals and dormitories in boarding schools, with a storey above 11 metres in height. It also reinforces the personal responsibility of all parties involved in the construction process.

Within those Building Regulations, sits BS EN8579:2020 – A Guide to the design of Balconies and Terraces, which puts further emphasis on the importance of fire safety in the drainage design of balconies and terraces. It scrutinises the use of combustible materials, such as plastics, in their construction and stipulates that components used should:

- Neither be composed of materials nor provide a medium for spread of fire

- Not propagate fire downwards by falling brands or flaming/molten droplets or debris

- Be designed to minimize the risk of becoming detached from the face of the building

- Minimize the risk of prejudicing the stability of the building from structural fire stress

Alumasc Water Management Solutions is the UK’s leading manufacturer of integrated non-combustible rainwater and drainage systems encompassing the entire building envelope. To address the newly introduced design requirements we have developed a fully-compliant drainage solution specifically suited to the rigours of high-rise building construction.

Alumasc Water Management Solutions is the UK’s leading manufacturer of integrated non-combustible rainwater and drainage systems encompassing the entire building envelope. To address the newly introduced design requirements we have developed a fully-compliant drainage solution specifically suited to the rigours of high-rise building construction.

The system incorporates Harmer Aluminium Roof Outlets featuring new extended spigots connecting directly to a welded spigot on Alumasc’s Aluminium Downpipes. Both products have a well-established track record of use in the high-rise building sector, but these new developments now present an efficient and compliant package which keeps our building industry colleagues up-to-date with ongoing regulatory changes.

The Harmer Aluminium Roof Outlet range is a high-performance rainwater drainage system suitable for all types of flat roof application, including balconies and terraces. The new spigots for connection to our aluminium downpipe systems eliminate any potential incompatibility which may occur when specifying unrelated products, resulting in quick, easy installation and its associated cost-savings. High flow performance and low maintenance provide complete reassurance which is critical to building drainage design.

Alumasc Aluminium Downpipes have a history of specification on many high-rise projects, and are available in a range of popular profiles. The inherent lightweight nature of aluminium makes them perfect for use at height, whilst their material hardness and fixing mechanisms, give excellent rigidity and high impact resistance.

Both Harmer Roof Outlets and Aluminium Downpipes are BBA approved powder coated, making them A2-s1, d0 fire rated, ensuring conformity to the new regulations in most applications.

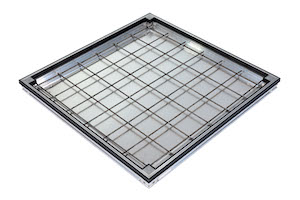

To complete the AWMS high-rise offer, the Harmer Modulock Pedestal System offers a range of non-combustible, raised pedestals designed to create level flooring in any building application where sloped, stepped or irregular surfaces present a challenge; perfect for balconies and terraces.

To complete the AWMS high-rise offer, the Harmer Modulock Pedestal System offers a range of non-combustible, raised pedestals designed to create level flooring in any building application where sloped, stepped or irregular surfaces present a challenge; perfect for balconies and terraces.

They are manufactured from mild steel with a highly durable zinc nickel, corrosion-resistant finish, making them A1 fire rated. The self-levelling head option is ideal for use with both paving slabs and timber, or a fixed head option is available for use with paving only.

This complete package of non-combustible outlets, downpipes and pedestals is 100% recyclable.

AWMS: Leading the way in non-combustible water management solutions

AWMS non-combustible drainage systems are underpinned by a solid company infrastructure which offers the following:

- three UK manufacturing plants

- national brand-specific sales team and regional support network

- in-house technical team

- design team to fulfil bespoke design requirements

- rainwater and drainage calculations and on-site surveys

- take off and estimations

- in-house, BBA approved powder coating facilities

- unrivalled dedicated UK technical and after-sales support

Alumasc Water Management Solutions is part of the Alumasc Group.

For more information, call 01536 383810 or visit www.alumascwms.co.uk