View the Radmat entry on BPindex

Environmental issues influence the construction industry at every stage of the building process. Government legislation and the Building Regulations have become more stringent with every update, requiring more sustainable approaches, and driving the industry to design, construct and deliver more energy-efficient buildings.

Environmental issues influence the construction industry at every stage of the building process. Government legislation and the Building Regulations have become more stringent with every update, requiring more sustainable approaches, and driving the industry to design, construct and deliver more energy-efficient buildings.

Building balconies and terraces over heated space is problematic for architects, designers and contractors: in new-build applications, stringent regulatory requirements and long-term economic viability have created greater demand for improved energy efficiency, while roofing designers and installers must strive to keep overall construction as thin as possible.

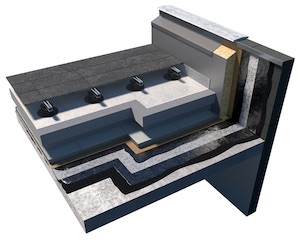

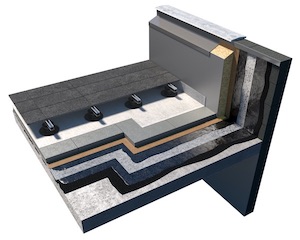

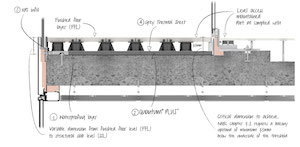

In order to meet the required U-values, the insulation will sometimes be installed both on top of and on the underside of the balcony or terrace. Not only can this be time-consuming, technically challenging and pose a condensation risk, it can also add unnecessary costs and increase the overall thickness of the construction.

There remains a huge industry demand for thinner and better performing products that will have a smaller impact on constructability and function in use. These limitations can significantly impact the ability to meet the requirements of Approved Document Part L Approved Document Part M and NHBC Chapter 7.1 when designing inverted roof constructions. Here the demand to insulate above habitable space can make it difficult for a designer to meet the backdrop of increasing thermal requirements whilst meeting the desire to maximise the glass façade and cater for a level threshold.

Inverted Roofing System market leader Radmat Building Products developed the ProTherm Quantum Inverted Roof Systems in 2014 to tackle exactly these issues, and in 2016 the BBA Certified ProTherm Quantum VIP Inverted Roof Systems; making it the first Vacuum Insulated Panel system to achieve such an accolade. Since then, ProTherm Quantum VIP has undergone continual development, resulting in the BBA Certifying ProTherm Quantum PLUS+ VIP Inverted Roof Systems in 2020.

Inverted Roofing System market leader Radmat Building Products developed the ProTherm Quantum Inverted Roof Systems in 2014 to tackle exactly these issues, and in 2016 the BBA Certified ProTherm Quantum VIP Inverted Roof Systems; making it the first Vacuum Insulated Panel system to achieve such an accolade. Since then, ProTherm Quantum VIP has undergone continual development, resulting in the BBA Certifying ProTherm Quantum PLUS+ VIP Inverted Roof Systems in 2020.

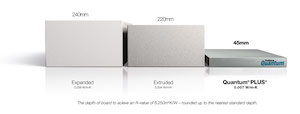

ProTherm Quantum PLUS+ consists of a rigid Vacuum Insulated Panel (VIP) robotically coated with an elastomeric waterproof coating, creating a robust ultra-high performance insulation panel with a Design Lambda value of 0.007 W/mK, potentially reducing insulation thickness to 72mm to achieve a 0.15 W/m2K U-value, as opposed to 220mm of Extruded Polystyrene (XPS) or 240mm of Expanded Polystyrene (EPS).

ProTherm Quantum PLUS+ can dramatically reduce the thickness of inverted roofing systems without compromising thermal performance whilst still achieving level thresholds. Suitable for use in roofs, roof terraces, podiums, enclosed balconies over heated space, insulated walkways, green roofs and blue roofs ProTherm Quantum PLUS+ provides the thinnest and most robust state of the art insulation system for inverted roof construction.

ProTherm Quantum PLUS+ can dramatically reduce the thickness of inverted roofing systems without compromising thermal performance whilst still achieving level thresholds. Suitable for use in roofs, roof terraces, podiums, enclosed balconies over heated space, insulated walkways, green roofs and blue roofs ProTherm Quantum PLUS+ provides the thinnest and most robust state of the art insulation system for inverted roof construction.

Whether designing an inverted roof to achieve the lowest possible Surface Slab Level to Finished Floor Level (SSL-FFL) or rectifying unexpected slab of floor level issues, ProTherm Quantum PLUS+ provides the thinnest insulation solution for a given u-value in roof, roof terrace, podium and balconies over heated space.

Whether designing an inverted roof to achieve the lowest possible Surface Slab Level to Finished Floor Level (SSL-FFL) or rectifying unexpected slab of floor level issues, ProTherm Quantum PLUS+ provides the thinnest insulation solution for a given u-value in roof, roof terrace, podium and balconies over heated space.

To ensure every project achieves an optimal solution Radmat’s in-house Quantum Design Team provide a full service, from initial outline design and thermal calculation to pre-delivery site survey, providing a final design solution with layout drawings for sign off. This comprehensive process considers the insulation thickness requirements early in the design process, highlighting potential threshold issues and providing the most cost effective solution to meet the target U-value.

To ensure every project achieves an optimal solution Radmat’s in-house Quantum Design Team provide a full service, from initial outline design and thermal calculation to pre-delivery site survey, providing a final design solution with layout drawings for sign off. This comprehensive process considers the insulation thickness requirements early in the design process, highlighting potential threshold issues and providing the most cost effective solution to meet the target U-value.