View the Advice entry on BPindex

Visit the Adveco website

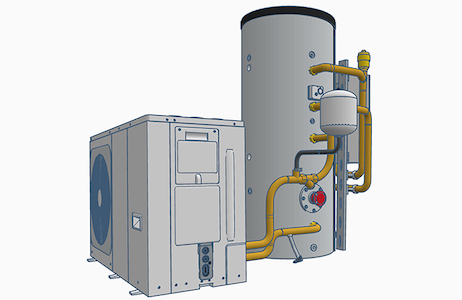

Adveco’s FUSION TW, a packaged electric water heating system for commercial projects, was named winner of the Commercial Heating Product of the Year category at the 2025 Energy Saving Awards. The Energy Saving Awards celebrate the very best professionals, products and projects across the Plumbing, HVAC and Energy Management sectors, acknowledging the important work that has been achieved by manufacturers, installers, contractors, suppliers and organisations to reduce carbon emissions and become more energy efficient.

Adveco’s FUSION TW, a packaged electric water heating system for commercial projects, was named winner of the Commercial Heating Product of the Year category at the 2025 Energy Saving Awards. The Energy Saving Awards celebrate the very best professionals, products and projects across the Plumbing, HVAC and Energy Management sectors, acknowledging the important work that has been achieved by manufacturers, installers, contractors, suppliers and organisations to reduce carbon emissions and become more energy efficient.

FUSION was conceived by the team at Adveco as a means of harnessing a hybrid approach to reduce energy demands and deliver a long-life low-carbon resolution for new build and gas-to-electric transition projects. It achieves this whilst avoiding costly oversizing and the need for bespoke system design, which raises costs and the impacts the feasibility of decarbonisation strategies.

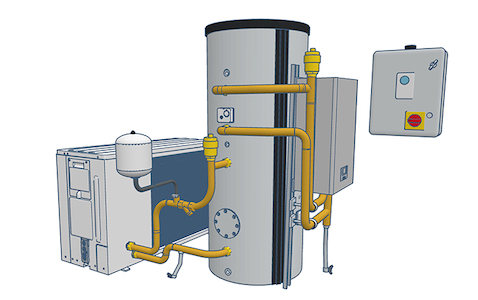

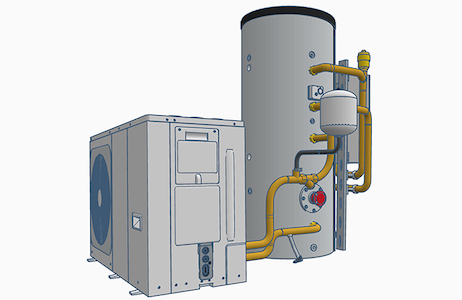

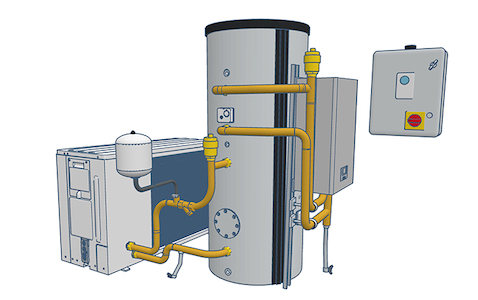

The all-new FUSION-TW and TWplus packages take the existing sealed primary loop combination of ARDENT electric boiler and 750-litre ATST twin-coil cylinder and reimagines the system with the integration of the ADV-W series of air source heat pumps.

This provides a wider choice of compact, pre-charged R32 ASHPs for generation of system preheat by either a 10 – 16 kW single-phase ADVS-W ASHP or a 16-30 kW ADV-W in three-phase capacity. With an A+++ ERP energy rating, and high SCOP with water outlet temperature 60° the ADV-W will maintain a consistent supply of hot water at up to 55° to pre-heat the FUSION system.

The TW-plus plus variants include either a 6 or 12 kW electric backup immersion for no single point of failure for assured delivery of hot water without downtime.

The TW-plus plus variants include either a 6 or 12 kW electric backup immersion for no single point of failure for assured delivery of hot water without downtime.

Greg Brushett, Sales Director, Adveco, said, “Winning at the 2025 Energy Saving Awards is another tremendous accolade for FUSION TW and reflects all the hard work the teams here at Adveco have invested in bringing a ground-breaking product to market. FUSION continues to change the way low-carbon water heating can be specified in commercial buildings. It allows for highly optimised applications which can be provided off-the-shelf in pre-sized, ready-to-go systems with a smaller footprint, that are easier to install, more efficient and cost-effective to purchase and operate. “

FUSION excels in the deployment of smart controls, maximising pre-heat input from the ADV-W series of heat pumps, capable of contributing as much as 70% of system heat requirements, and balancing this with the primary input of the ARDENT electric boiler so that the two heat sources blend harmoniously, offsetting as much direct electric demand as possible. FUSION’s new enhanced controls not only optimise the mixture of pre-heat from the heat pump, but they also manage the elements within the electric boiler and backup immersion. If this is not managed correctly by the controls, the two heat sources would act in contention, countering system efficiency and wasting energy. This also ensures the electric boiler is not required to work as hard to raise flow temperatures to the 65°C demanded by commercial applications, reducing maintenance demands and improving the longevity of the boiler.

Adveco has released new single- and three-phase control panels supporting both ADVS-W and ADV-W variant ASHP. Time control clock controls are built-in, as is thermal disinfection. When connected to the BMS, disinfection and high-temperature pasteurisation functions can also be monitored when active, and a fault relay can be instigated. The new panels support connections for the LLH pump, lighting, socket, heater bar, secondary return pump and destratification pump output. With the inclusion of a GSM module, fault notifications can be enabled from the BMS or via text. The new controls also provide the option to prevent immersion activation when ASHP goes into fault to limit current.

Adveco has released new single- and three-phase control panels supporting both ADVS-W and ADV-W variant ASHP. Time control clock controls are built-in, as is thermal disinfection. When connected to the BMS, disinfection and high-temperature pasteurisation functions can also be monitored when active, and a fault relay can be instigated. The new panels support connections for the LLH pump, lighting, socket, heater bar, secondary return pump and destratification pump output. With the inclusion of a GSM module, fault notifications can be enabled from the BMS or via text. The new controls also provide the option to prevent immersion activation when ASHP goes into fault to limit current.

Specification allows for the selection of a system based on nominal power output (kW), storage capacity (litres), continuous flow (litres/hour), instantaneous draw off capacity (litres) and peak draw off (litres). This offers 25 base variants of the TW, each supporting the addition of an incorporated backup electric immersion (TWplus).

When comparing TW and TWplus systems to equivalent direct electric DHW systems, offset energy use delivers carbon emission savings starting at 20.53% climbing to 47.75%. Across the entire range, we can see an average of 36.3% savings versus other direct electric systems.

When calculating the carbon emissions savings for FUSION TW, they become more notable when compared to gas-fired systems. Starting at 51.11% and climbing to as much as 67.86%. Across the entire range, we can see an average of 60.8% savings versus the latest generation of gas water heater systems.

By embracing an indirect approach to water heating with a primary loop configuration FUSION is also able to provide assured operation which fully counters the effects of limescale in hard water areas, whilst its tough, stainless steel build is more than strong enough to prevent the corrosive action of soft water, making it a truly universal system no matter local water quality.

“Hybrid systems have the potential to be complex and come with greater capital expense, especially at a commercial scale,” Greg observes. “Adveco’s award-winning FUSION TW with ADV-W ASHP counters this with a far more compact monobloc form factor to lower entry costs for ASHP-based water heating and drive the uptake of sustainable systems in the UK.”

ADVECO FUSION TW/TWplus Key features

FUSION TW

- High-quality ATST twin coil stainless steel vessel with mounting points & brackets

- Available in 300 – 750 litre capacities

- Cylinder pressure 10 bar as standard

- 9, 12 or 24 kW electric boiler

- 10, 12 or 16 kW single-phase air source heat pump

- 16, 22 & 30 kW three-phase air source heat pump

- Pre-built pipework (left or right)

- FUSION Control Box

- Compact space-saving form factor

- 25 pre-sized variants from 19 to 52 kW

FUSION TWplus

- 6 kW or 12 kW electric immersion

- FUSION Control Box & GSM remote alerts

- 25 pre-sized variants from 19 to 52 kW

https://adveco.co/products/water-heating/fusion-packaged-electric-water-heaters/

CPD events will be delivered by our highly experienced team of Certificated Surveyors in Structural Waterproofing (CSSW). They deliver over one-hundred RIBA-approved CPDs throughout the year to architects, engineers and construction professionals across the country.

CPD events will be delivered by our highly experienced team of Certificated Surveyors in Structural Waterproofing (CSSW). They deliver over one-hundred RIBA-approved CPDs throughout the year to architects, engineers and construction professionals across the country. Furthermore, our latest RIBA-approved CPD on Specifying Pumping Systems for Below-Ground Waterproofing Projects will also be available both online and in-person.

Furthermore, our latest RIBA-approved CPD on Specifying Pumping Systems for Below-Ground Waterproofing Projects will also be available both online and in-person.