View the EJOT entry on BPindex

From contractor to installer, whoever is purchasing building fasteners from within the project chain is linked to the overall investment of the complete building system. Modern technical fastening products are engineered components in their own right and when installed correctly they provide high strength load performance, safe and secure joints, environmental longevity and many other application benefits.

The demands that go hand in hand with today’s construction industry require manufacturers of all contributing components to be vigilant, knowledgeable and fully transparent. As original fastening manufacturers EJOT is in a strong position to monitor such technical demands. Research and Development is key and with EJOT’s global market interests spanning sectors such as aerospace, automotive, seismic and nuclear construction, cross-pollination of technical knowledge can and has created cutting-edge solutions for many building and construction fastening products.

The demands that go hand in hand with today’s construction industry require manufacturers of all contributing components to be vigilant, knowledgeable and fully transparent. As original fastening manufacturers EJOT is in a strong position to monitor such technical demands. Research and Development is key and with EJOT’s global market interests spanning sectors such as aerospace, automotive, seismic and nuclear construction, cross-pollination of technical knowledge can and has created cutting-edge solutions for many building and construction fastening products.

If knowledge is the cornerstone to specification, sharing knowledge is of course the responsibility of the manufacturer. With reference to the correct deployment of technical fasteners, ‘best practice’ also implies the need for contractors to see the entire installation process through, yet this can break down if everyone actively involved in the chain is not fully aware of the technical properties that a modern fastener is engineered to deliver.

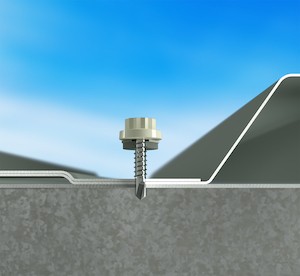

Seeing first-hand such varying levels of technical awareness, EJOT UK has produced the first in a new series of video and printed guides. Here, the company’s technical wing ‘EJOT Applitec’, reviews best installation practices relating to self-drilling fasteners. The Yorkshire based manufacturer is keen to convey how vast choice of drive tools through to installation techniques can affect the end result and how combinations of torque, loading and installation speeds are absolutely vital.

For example, market-wide installation tools range from dry-lining guns through to impact drivers which are all compact and relatively inexpensive. Yet unlike professional screw guns, the general mechanics of these devices will often mean they can apply an unnecessary and uncontrollable amount of torque to fasteners that need to be installed to precise settings. Many of these tools have no clutch mechanism to safeguard against over-driving and whilst it may be possible to achieve a correctly installed fastener using such drivers, at best the installer is doing so by ‘guesswork’ – which simply cannot be relied upon across the installation of several thousand fasteners. The same concerns apply across the huge variety of fasteners and applications that the industry now demands. The clear risk here is that the original construction investment is at best diluted, with reputations and overall responsibilities in sharp focus should performance integrity be lost.

For example, market-wide installation tools range from dry-lining guns through to impact drivers which are all compact and relatively inexpensive. Yet unlike professional screw guns, the general mechanics of these devices will often mean they can apply an unnecessary and uncontrollable amount of torque to fasteners that need to be installed to precise settings. Many of these tools have no clutch mechanism to safeguard against over-driving and whilst it may be possible to achieve a correctly installed fastener using such drivers, at best the installer is doing so by ‘guesswork’ – which simply cannot be relied upon across the installation of several thousand fasteners. The same concerns apply across the huge variety of fasteners and applications that the industry now demands. The clear risk here is that the original construction investment is at best diluted, with reputations and overall responsibilities in sharp focus should performance integrity be lost.

The guide also illustrates how to achieve correct settings that relate directly to the different type of the materials being joined, the easiest way to achieve and determine successful application, and finally how to monitor safe and correct installation throughout the project’s schedule.

The guide also illustrates how to achieve correct settings that relate directly to the different type of the materials being joined, the easiest way to achieve and determine successful application, and finally how to monitor safe and correct installation throughout the project’s schedule.

Brian Mack is Technical Business Development Manager for EJOT in the UK:

“The information we are producing here shows that we don’t just sell fastening products. The responsibility goes much further than that and we are working alongside other manufacturers to develop responsible technical information that supplements in greater detail the contributions we make collectively, to information circulated by recognised industry flag bearers such as the NFRC and the MCRMA”.

To further endorse the company’s commitment to Best Practice, EJOT UK has sponsored the NFRC’s industry-wide reference manual, known as ‘The Blue Book’. Managing Director Robert Hardstaff said:

“EJOT UK shares the NFRC’s philosophy of quality and excellence within the construction industry. We are therefore delighted that as NFRC Industry Technical Partner, our sponsorship will help to support this industry-wide platform for best practice.”

More information about accessing EJOT’s technical guide is now available at