DEFINING EXTERNAL WALL INSULATION

Image Location: Beacon Avenue Exeter

Construction materials and products are constantly evolving to keep up with the pace of the construction industry, consequently, we have seen a dramatic increase in the number of timber frame houses being built.

Construction materials and products are constantly evolving to keep up with the pace of the construction industry, consequently, we have seen a dramatic increase in the number of timber frame houses being built.

With the growth of modular construction utilising off-site construction there has been a decrease in time spent on site, creating consistency and increased productivity.

The energy efficiency of our homes has also become a concern with rising heating costs, meaning more of us are thinking about other innovative solutions like the insulation of our homes.

ICF or insulated concrete form is a fantastic example of a modern system focused on creating exceptionally energy-efficient homes.

ICF or insulated concrete form is a fantastic example of a modern system focused on creating exceptionally energy-efficient homes.

ICF is quick to install by stacking polystyrene blocks, filling the hollow with concrete and leaving it to set, resulting in an incredibly strong and thermally efficient structure.

But what about existing houses! Improvement of loft insulation and underfloor insulation can make a notable difference, but what about the walls?

![]() Cavity wall insulation is a popular solution for many homes, although not all housing stock is suitable.

Cavity wall insulation is a popular solution for many homes, although not all housing stock is suitable.

This leaves two main options, increase the insulation inside the house with internal insulation systems, or look at an external insulation system.

External insulation systems are a fantastic way to increase the insulation value of your house while transforming the look of the building.

At SAS, we have developed ProRend EIFS, our comprehensive and fully warranted external insulation system.

![]() THE ADVANTAGES OF USING PROREND EIFS:

THE ADVANTAGES OF USING PROREND EIFS:

- Choice of EPS or Mineral wool insulation to suit your requirements

- Fire tested in accordance with BS-EN 13501 Achieving a rating of A2-S1-D0 (for mineral wool)

- Drastically increase property’s thermal performance

- Approved Document Part B Fire Safety compliant

- Suitable for application up to and above 18m (mineral wool)

- Available in 30 standard colours plus RAL and NCS matching to 65000+ colours

- 10-year system warranty

- Highly water-repellent silicone resin finish

- Low maintenance costs

SYSTEM BREAKDOWN

Following any potential surface preparation requirements, the insulation material, either mineral wool or EPS, is adhered to the surface using our specially designed high polymer basecoat.

The insulation slabs are mechanically fixed to the substrate, then the basecoat is applied and fully embedded with a fibreglass reinforcement mesh to tie the whole area together.

Once cured, a colour primer is applied followed by a highly water-resistant and flexible silicone thin coat.

The whole system achieves a 30-year BBA certification and comes with a 10-year system warranty.

INSULATION OPTIONS:

ProRend EIFS can be installed using either expanded polystyrene (EPS), or mineral wool insulations.

Both options of ProRend EIFs boast superb insulation properties but principally for different property types.

THE ADVANTAGES OF USING EIFS: EXPANDED POLYSTYRENE – EPS

Our premium platinum insulation has fantastically low thermal conductivity, drastically decreasing the overall heat lost through your walls.

As the most cost-effective of the two insulants, EPS is often the material of choice for residential renovations.

MINERAL WOOL

Our high-density mineral wool slab is a fibrous material formed by spinning or drawing molten mineral or rock materials.

The composition of the mineral wool makes it incredibly fire-resistant; this is particularly useful for any high rise or commercial buildings where fire safety is paramount.

Mineral Wool can be utilised as a sole insulant in ProRend EIFS projects or serve as a fire barrier in EPS applications.

When considering a renovation to improve thermal efficiency, the regulations refer to the thermal requirements as stated in Approved Document L1B.

When considering a renovation to improve thermal efficiency, the regulations refer to the thermal requirements as stated in Approved Document L1B.

L1B states that any newly constructed thermal elements or thermal elements constructed as replacements for existing elements should achieve a U-value of 0.28 W/(m².K).

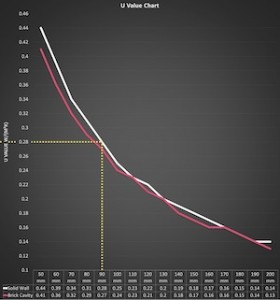

Two traditional wall makeups are solid walls or brick cavities. We have modelled the reduction in U-value based on various thicknesses of EPS used in our system.

As you can see from the graph, 90mm insulation is often enough to meet the regulations of 0.28 W/(m².K).

Thicker insulation can, of course, be used to further decrease the U-value and make the building that much more thermally efficient.

Whatever your property, if you are looking to increase the thermal efficiency while transforming the exterior, get in touch and SAS will put a bespoke specification together for you and calculate your U-value.