View the DuPont™ Tyvek® entry on BPindex

Visit the DuPont™ Tyvek® website

Student housing in Sweden:

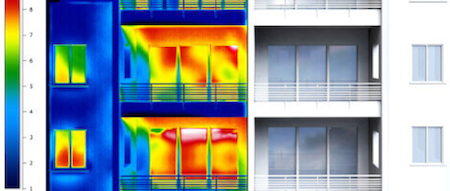

Forta Pro modular solutions with DuPont™ Tyvek® deliver energy efficiency and increase interior comfort.

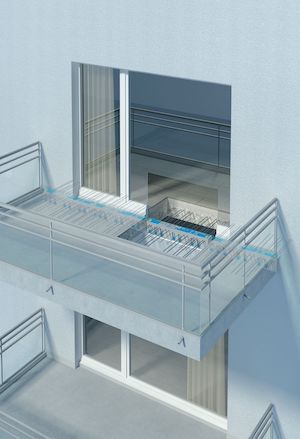

April 2021 – “Kvarteret Jylland” is a new student accommodation consisting of 350 micro-apartments), located in Kista, Northern Stockholm, Sweden. The project mission was to build modern, sustainable and attractive premises for young people. The Kvarteret Jylland complex (7100 square metres, four buildings) was completed in a short amount of time by the Latvian-based company Forta Pro, that specializes in modular construction solutions based on energy efficiency and sustainability concepts. 178 modules were fabricated and installed. DuPont™ Tyvek® breathable membranes and accessories have been used by Forta Pro for the building envelope to protect the construction from water, air and moisture and to increase the comfort and well-being of the students.

Kvarteret Jylland student accommodation, in Kista (Stockholm, Sweden), built by Forta Pro company.

Forta Pro’s modular solutions deliver energy efficiency and use DuPont™ Tyvek® breathable membranes

and accessories for the building envelope; photos courtesy of Forta Pro, all rights reserved.

Modular construction is a process that uses off-site, prefabricated building methods. It ensures better construction quality management and less disruption. Projects can be completed up to 50% quicker than traditional construction methods. The pre-engineered structures are manufactured and assembled off-site

in a factory-controlled environment. DuPont building materials provide holistic solutions that fulfill the requirements of this housing project, of modular construction techniques, and improve energy efficiency.

DuPont™ AirGuard® vapour control membranes were used with the internal insulation to deliver superior airtightness. These membranes are extremely resistant, lightweight, flexible and easy to install, they maintain their characteristics over time and help to optimize the building performance. A DuPont™ Tyvek® Tape was used to join the membranes and create a continuous barrier with no leakage.

Kvarteret Jylland student accommodation, in Kista (Stockholm, Sweden), built by Forta Pro company. Forta Pro’s modular solutions deliver energy efficiency and use DuPont™ Tyvek® breathable membranes and accessories for the building envelope; photos courtesy of Forta Pro, all rights reserved.

On the exterior walls, a Tyvek® vapour-permeable and water-resistant membrane provides high performance protection from weather conditions. To create an optimum building envelope, DuPont™ Tyvek® Flex Wrap was used to seal the outer construction penetrations such as pipes and conduits.

Inside, a Tyvek® tape seals around the window frames. With their wide variety of products and world-class technical know-how, DuPont Performance Building Solutions help building and construction

professionals and companies to meet the new and demanding requirements in terms of airtightness and increased energy efficiency.

“The Kvarteret Jylland project was challenging in many ways and it was essential to cooperate with our partners for a successful outcome. From the beginning, we rely on partners like DuPont who can assist us throughout the entire process with daily contact, training in our production facility and technical support. We have been using Tyvek® membranes and accessories for a few years and they help us in finding solutions to the challenges brought by our clients, both in terms of installation, airtightness and energy efficiency. DuPont always provides us with high-quality materials backed by a warranty, with continuous support and they understand our requirements, all within reasonable costs.” said Jānis Priede, Project manager, Forta Pro.

Kvarteret Jylland student accommodation, in Kista (Stockholm, Sweden), built by Forta Pro company. Forta Pro’s modular solutions deliver energy efficiency and use DuPont™ Tyvek® breathable membranes and accessories for the building envelope; photos courtesy of Forta Pro, all rights reserved.

While working on the off-site manufacturing, Forta Pro proceeded with the work on the construction site, which led to major time savings. The pre-fabricated modules, assembled on-site, created four multi-storey buildings with high standard, comfortable accommodations. The synergy between the Forta Pro process and DuPont™ Tyvek® and AirGuard® products – all backed by a DuPont warranty – allowed them to build modern, sustainable and attractive premises for the students in Kista.

About Forta Pro (fortapro.com) – Based in Riga, Latvia, Forta Pro company uses a modular construction techniqueenabling the development of environmentally sustainable buildings, contributing also to saving energy and time during the construction process. The company produces – in its fast and cost-effective linear production line with a large production capacity – high standard modular units suitable for multiple-story facilities construction.

Forta PRO features advanced off-site building methods offering a fast-track modular and construction solutions with minimal disruption to the operation of surrounding facilities. The advanced prefabrication enables Forta PRO to speed-up the timetable for construction projects in a way that is not achievable by the on-site building technology. Strict quality control implemented in our modern factory and supported by Forta PRO multi-disciplinary professional team provides a guaranteed comprehensive quality solution. Forta PRO can plan, design, and build from scratch or expand existing facilities.

Forta Pro’s modular solutions deliver energy efficiency and use DuPont™ Tyvek® breathable membranes and accessories; photos courtesy of Forta Pro, all rights reserved.

Forta Pro’s modular solutions deliver energy efficiency and use DuPont™ Tyvek® breathable membranes and accessories; photos courtesy of Forta Pro, all rights reserved.

About DuPont Performance Building Solutions – A division of the Water & Protection segment of DuPont, DuPont Performance Building Solutions is a global innovation leader in the building and construction industry, providing products and materials for the building envelope.

With today’s focus on the reduction of emissions and improved energy efficiency, you can count on brands such as Tyvek®, AirGuard®, Great Stuff™, Insta Stik™, Froth-Pak™ and LiquidArmour™ that have been at the heart of building solutions for decades backed by unmatched industry insight, building knowledge, and technical support. The products and services portfolio of DuPont Performance Building Solutions enables customers to focus on what they do best, no matter where and how they choose to build. To know more about DuPont Performance Building Solutions, www.building.dupont.com

In support of its aspiration to lead and partner in delivering solutions that transform how lasting affordable shelter is created for people around the world, DuPont Performance Building Solutions (PBS) has set a

series of Sustainability Goals, aligned within the framework of DuPont’s 2030 Sustainability Goals. Specifically, DuPont Performance Building Solutions aspires to:

- Direct 100 percent of the innovation portfolio to meaningfully advance the United Nations Sustainable Development Goals (UN SDGs) and create value for customers;

- Reduce greenhouse gas (GHG) emissions from operations by 75 percent from 2019 levels;

- Advance the circular economy in the building industry through innovation in materials and business models, collaboration, and end-of-life plans that eliminate and upcycle waste across the product life cycle;

- Collaborate with customers and partners to bring green chemistry innovations to market and will drive continued reduction in the presence of priority substances in the product portfolio;

- Work to build communities, strengthen families, and empower the next generation across the globe.

About DuPont – DuPont (NYSE: DD) is a global innovation leader with technology-based materials and solutions that help transform industries and everyday life. Our employees apply diverse science and expertise to help customers advance their best ideas and deliver essential innovations in key markets including electronics, transportation, construction, water, healthcare and worker safety. More information about the company, its businesses and solutions can be found at www.dupont.com.

Noisy pipes present a challenge in multi-storey buildings all over the world. Whether hospitals, hotels, residential developments or offices, pipe noise can be far costlier to fix post-build than if addressed during planning. Building on the successful 30-year plastic low-noise legacy of the Wavin AS system, the new and improved Wavin AS+ solution provides advanced noise reduction in soil and waste systems.

Noisy pipes present a challenge in multi-storey buildings all over the world. Whether hospitals, hotels, residential developments or offices, pipe noise can be far costlier to fix post-build than if addressed during planning. Building on the successful 30-year plastic low-noise legacy of the Wavin AS system, the new and improved Wavin AS+ solution provides advanced noise reduction in soil and waste systems.