View the DuPont™ Tyvek® entry on BPindex

Visit the DuPont™ Tyvek® website

Using DuPont Tyvek® and AirGuard® construction membranes and accessories Melius Homes re-skins

walls and roof with modern materials that provide greatly enhanced performance,

protecting the occupants from the harmful effects of heat, moisture and air leakage.

Photos courtesy of Melius Homes, all rights reserved.

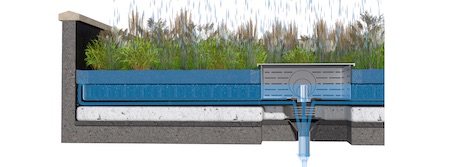

Melius Homes (www.meliushomes.co.uk) is a building firm with a clear philosophy: build high quality, affordable, flexible new homes and transform existing dwellings into energy efficient, comfortable and healthy homes Rather than demolish structurally sound houses, Melius Homes re-skins walls and roofs with modern materials that provide greatly enhanced performance, protecting the occupants from the harmful effects of heat, moisture and air leakage. In order to achieve these goals and to be suitable for use in any location, Melius Homes specified a selection of DuPont construction membranes and accessories.

“With this project, we retain the existing building, and therefore it’s embodied energy. We encapsulate it to provide minimal air leakage, typically < 1m3/hr/m2. This is an improvement of greater than 90% over the building regulations and can be applied to almost any existing structure, whatever its type, across the whole of the UK.” said Paul Clark, Design Manager at Melius Homes.

On the wall panels warm side, DuPont™ AirGuard® SMART is incorporated as the AVCL and this provides a 100% airtight layer, combined with a controlled level of vapour resistance, in order to minimize convected heat losses. On the external, cold side of the Melius Homes panel, a W1 rated DuPont™ Tyvek® Reflex is fitted, and this means that not only can the panels be used in any exposure area, the uniquely lacquered, metallised surface, provides a protected low-e material, to permanently boost the performance of the insulation. DuPont™ Tyvek® Metallised tape is used to seal the membrane laps and maintain the systems thermal performance.

On the roof panels, a similar build up is employed, but here a layer of DuPont™ Tyvek® Supro underlay is used. Unrestricted when tested to BS5534 +A2 2018, Tyvek® Supro can also be used in any location in the UK, regardless of site location, height above sea level, proximity to water, site topography and ceiling condition. Adding to the convenience is the roll size – being 3.0 x 50m means minimizing overlaps which increases the speed of installation in the factory.

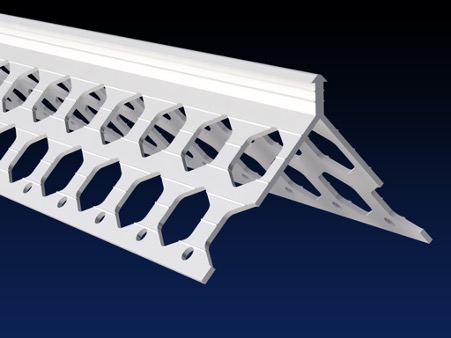

All buildings have penetrations and here, Melius Homes make use of DuPont™ Tyvek® Flexwrap EZ. The flexible nature of Tyvek® Flexwrap (a 1m length will stretch to 1.6m) makes it ideal for any sealing application, regardless of shape or size, with the need for separate grommets eliminated.

“We never seemed to have the correct size for the job! Tyvek® Flexwrap EZ means that all we need to do is cut it to length and this, in turn, means that there is no waste, an important consideration when constructing low carbon homes”, commented Paul Clark.

Quick and easy to install, the Melius Homes approach, and the Tyvek® and AirGuard® membranes and accessories that are used, ensures the best performance possible and utilises the best of both worlds – retained masonry construction for thermal mass and timber panels for maximum thermal performance and airtightness. This is vital because airtightness ensures that the system performs “as designed”, with virtually no performance gap, and keeps heating bills to a minimum.

Using DuPont Tyvek® and AirGuard® construction membranes and accessories Melius Homes re-skins

walls and roof with modern materials that provide greatly enhanced performance,

protecting the occupants from the harmful effects of heat, moisture and air leakage.

Photo courtesy of Melius Homes, all rights reserved.

About Melius Homes (www.meliushomes.co.uk) – Melius Homes brings years of experience to the challenge of creating a bespoke home with the consistency and reliability of a manufactured product. Their homes are built in a systematic and controlled way, with much of the fabrication undertaken in an enclosed factory environment.

This approach allows the firm to manage the construction and assembly processes with real rigour. Factory fabrication reduces the number of construction faults and improves the internal fit and finish of materials, built-in fittings and appliances in bathrooms and kitchens. The same approach is applied to the vital ‘hidden’ elements – the wiring, plumbing, heating and ventilation systems – that form an increasingly important role in new, low-energy cost homes.

About DuPont Performance Building Solutions – A division of the Water & Protection segment of DuPont, DuPont Performance Building Solutions is a global innovation leader in the building and construction industry, providing products and materials for the building envelope. With today’s focus on the reduction of emissions and improved energy efficiency, you can count on brands such as Tyvek®, AirGuard®, Great Stuff™, InstaStik™ and Froth-Pak™ that have been at the heart of

building solutions for decades backed by unmatched industry insight, building knowledge, and technical support.

The products and services portfolio of DuPont Performance Building Solutions enables customers to focus on what they do best, no matter where and how they choose to build. To know more about DuPont Performance Building Solutions in the UK, please visit https://www.dupont.co.uk/building.html

In support of its aspiration to lead and partner in delivering solutions that transform how lasting affordable shelter is created for people around the world, DuPont Performance Building Solutions

(PBS) has set a series of Sustainability Goals, aligned within the framework of DuPont’s 2030 Sustainability Goals. Specifically, DuPont Performance Building Solutions aspires to:

- Direct 100 percent of the innovation portfolio to meaningfully advance the United Nations Sustainable Development Goals (UN SDGs) and create value for customers;

- Reduce greenhouse gas (GHG) emissions from operations by 75 percent from 2019 levels;

- Advance the circular economy in the building industry through innovation in materials and business models, collaboration, and end-of-life plans that eliminate and upcycle waste across the product life cycle;

- Collaborate with customers and partners to bring green chemistry innovations to market and will drive continued reduction in the presence of priority substances in the product portfolio;

- Work to build communities, strengthen families, and empower the next generation across the globe.

About DuPont – DuPont (NYSE: DD) is a global innovation leader with technology-based materials and solutions that help transform industries and everyday life. Our employees apply diverse science and expertise to help customers advance their best ideas and deliver essential innovations in key markets including electronics, transportation, construction, water, healthcare and worker safety. More information about the company, its businesses and solutions can be found at www.dupont.com.

DuPont™, the DuPont oval logo, Tyvek®, the Tyvek® logo system and all other products denoted with ™ or ® are registered trademarks or trademarks of affiliates of DuPont de Nemours Inc., unless differently specified. Other logos, trademarks and registered trademarks are a property of their respective owners.