View the Eurocell entry on BPindex

Visit the Eurocell website

Purpose-built student accommodation developer sees the all-round value of PVC-U window specification at new flagship accommodation project for major university.

Developers of purpose-built student accommodation (PBSA) solutions are seeking a combination of cost efficiency, sustainability advantages, high performance, and aesthetic appeal when it comes to product specification.

Developers of purpose-built student accommodation (PBSA) solutions are seeking a combination of cost efficiency, sustainability advantages, high performance, and aesthetic appeal when it comes to product specification.

Eurocell has once again worked with Future Generation – specialists in the development and design of exceptional student accommodation projects – to help deliver a stunning new student housing development.

The two organisations had partnered at another PBSA development at Hythe Mills, Colchester for another big university. Such was its success that the two companies have now collaborated on another prestigious project which has been described in the media as ‘the jewel in the crown’ for the UK’s fast growing PBSA sector.

The newly completed £40 million Guilden Village development in Guildford opened in August 2021 after a three-year build timetable and has now welcomed its first students for the 2021/22 academic year. It showcases modern, spacious, and affordable accommodation in which tenants are happy to live, study and enjoy their much-anticipated student experience.

The newly completed £40 million Guilden Village development in Guildford opened in August 2021 after a three-year build timetable and has now welcomed its first students for the 2021/22 academic year. It showcases modern, spacious, and affordable accommodation in which tenants are happy to live, study and enjoy their much-anticipated student experience.

The specification of Eurocell’s high quality Modus Slim Sash Windows in within the 533-student room development, provides an aesthetically appealing option for the exterior and substantial sustainability benefits – all based on MODUS Slim Sash’s unique ability to deliver an aesthetically very similar window to aluminium whilst improving thermal performance at a significantly lower cost.

The new purpose-built student accommodation uses the Eurocell Modus solution across all the bedrooms, and it complements the holistic visual appeal of the entire development which also includes a state-of-the-art gym, cinema room, multiple study rooms, and off-street parking.

The new purpose-built student accommodation uses the Eurocell Modus solution across all the bedrooms, and it complements the holistic visual appeal of the entire development which also includes a state-of-the-art gym, cinema room, multiple study rooms, and off-street parking.

Gary Driscoll, sales & commercial director at Eurocell explains: “Having successfully worked to specify the window solution at the Future Generation Colchester project, Eurocell were delighted to be invited once again to work alongside the company to create an appropriate and high-performing PVC-U window solution to support the exciting plans at the larger Guilden Village site.

“Future Generation directed the development’s design team that the Eurocell product should be considered and after discussions around desired aesthetics, performance versus cost, sustainability ambitions and safety, we collectively agreed that the Modus Slim window profile was the best choice.

“By using PVC-U instead of aluminium, not only did the project gain technical performance advantages against cost, but it also gained important long-term benefits through the specification of a highly sustainable product solution that is a tangible answer to counter today’s environmental challenges.”

Sustainable window solutions

Eurocell uses its own recycling plants to transform old waste PVC-U window and door frames into new PVC-U profiles through a closed loop recycling scheme. By doing so it is supporting sustained efforts by the construction industry to increase the prevalence of greener solutions to help build a more sustainable world.

Preventing discarded PVC-U frame waste from ending up in landfill and using it to create new PVC-U profiles is Eurocell’s proactive response to the climate crisis, and one that is finding real traction with like-minded companies looking to do the right thing when it comes to making sustainable product choices. This approach has been employed on the Guilden Village project, with the installed Eurocell Modus Slim window profiles emanating from a recycled source.

Eurocell worked with the fabrication and installer team at Astraseal Ltd to ensure the profile and fabrication process maintained the required momentum and supported the construction timetable. Planning approval for the window specification was obtained without any issues, with the authorities satisfied that the Modus Slim Sash PVC-U solution provided a seamless match to the overall design vision.

Building on the positive experience of the Hythe Mills project, Guilden Village is another strong example where project collaboration has identified an alternative product solution which matches design aspiration, drives the vital sustainability agenda, guarantees high performance and, ultimately, saves the client money.

Gary concludes: “Eurocell and Future Generation are delighted with the outcome of our ongoing collaborative partnership within the PBSA sector. The developer’s Guilden Village and Hythe Mills PBSA projects are helping to answer the ongoing and pressing need for high standard student accommodation to support those pursuing their education ambitions. Eurocell’s great looking, sustainable and high-performing PVC-U window solutions aim to assist developers such as Future Generation ensure market demand in a booming sector continues to be satisfied.”

If you would like to speak to us about how we can help on your next project email us at enquiries@eurocell.co.uk or call on 0333 005 6525 to discuss your requirements.

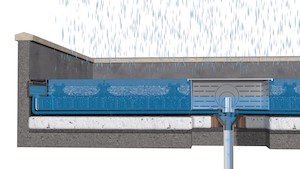

The hollow soffit has been redesigned to include more ‘webs’ – referring to the UPVC matrix inside the soffit – to create a stronger core to make the boards more durable. Importantly for installers, the redesign has also improved the way the boards push together making them faster to fit as well as improving ease of use on site.

The hollow soffit has been redesigned to include more ‘webs’ – referring to the UPVC matrix inside the soffit – to create a stronger core to make the boards more durable. Importantly for installers, the redesign has also improved the way the boards push together making them faster to fit as well as improving ease of use on site.