View the Geggus entry on BPindex

HIGH QUALITY & OUTSTANDING PERFORMANCE

Supplied and managed exclusively in the UK by MMA Architectural Systems, each Geggus entrance matting system is designed to meet customers’ individual project requirements. Manufactured to order in Germany, Geggus high-quality, high-performance systems are suitable for both new build and retrofit projects.

Supplied and managed exclusively in the UK by MMA Architectural Systems, each Geggus entrance matting system is designed to meet customers’ individual project requirements. Manufactured to order in Germany, Geggus high-quality, high-performance systems are suitable for both new build and retrofit projects.

The systems provide the perfect solution for a huge range of projects, from offices to hotels, restaurants to airports and shopping malls to car showrooms – and not only for entrance areas, but also for other areas of a building, such as access points, lift landings and canteen entrances – in fact, anywhere that may see high foot traffic and so may be at risk from dirt and heavy wear.

YOU ONLY GET ONE CHANCE TO MAKE A GREAT FIRST IMPRESSION

A building’s entrance provides the perfect opportunity to make a great first impression, with architects and interior designers striving to make these areas impactful and reflective of the values of the business or brand.

A building’s entrance provides the perfect opportunity to make a great first impression, with architects and interior designers striving to make these areas impactful and reflective of the values of the business or brand.

First impressions are so important, with visitors starting to form opinions about the building and its occupiers from the moment they walk through the door. A bespoke Geggus entrance matting system can help make sure that it’s a memorable experience.

EFFECTIVE, VERSATILE, DURABLE – AND SILENT

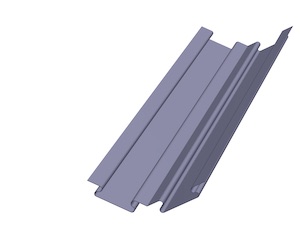

Entrance matting systems not only have to perform by keeping an area clean and safe, but they also have to complement the overall look and feel of an entrance area. Geggus systems perform all these tasks effortlessly. They effectively capture dirt and moisture to provide a safe and effective barrier, helping to reduce the risk of slips, trips and falls – while enhancing the overall aesthetics of their surroundings. In doing this, entrance matting systems also help keep cleaning and maintenance costs down, ensuring that reception areas and internal floors always look at their best. Unlike other systems, Geggus matting is also almost silent to walk over, thanks to its unique design which virtually eliminates impact sound.

Entrance matting systems not only have to perform by keeping an area clean and safe, but they also have to complement the overall look and feel of an entrance area. Geggus systems perform all these tasks effortlessly. They effectively capture dirt and moisture to provide a safe and effective barrier, helping to reduce the risk of slips, trips and falls – while enhancing the overall aesthetics of their surroundings. In doing this, entrance matting systems also help keep cleaning and maintenance costs down, ensuring that reception areas and internal floors always look at their best. Unlike other systems, Geggus matting is also almost silent to walk over, thanks to its unique design which virtually eliminates impact sound.

OUTSTANDING SERVICE FROM AN EXPERIENCED TEAM

With over 75 years’ experience, Geggus can provide expert advice on your entrance matting needs, making sure that your matting system not only looks great, but also delivers many years of reliable performance.

With over 75 years’ experience, Geggus can provide expert advice on your entrance matting needs, making sure that your matting system not only looks great, but also delivers many years of reliable performance.

If required, a Geggus engineer will visit your site to take detailed measurements prior to manufacture – and then carry out the installation. This service applies to both new buildings and existing buildings and for installing new mats or replacing existing ones, so that when installed, you can be confident that the entrance matting system fits precisely and will withstand the stress and loads that foot traffic will place on it.

With excellent delivery times, the team aims to make sure your programme flows as smoothly, quickly, and efficiently as possible and will guide you at every stage, from providing samples and designs right through to supply, installation and maintenance.

Whether you are looking for a specific entrance matting system, or need advice on the most appropriate system for your project, the team is happy to assist you.

Please contact us to discuss your requirements.

Phone: +44 01761 419 427

E-Mail: info@geggus.co.uk

Web: www.geggus.co.uk