View the Graphenstone entry on BPindex

View the Graphenstone entry on BPindex

Visit the Graphenstone website

Mineral and graphene technology paints company GRAPHENSTONE, are reporting sharply increased demand for their sustainable range of air-purifying, CO2 absorbing, VOC free hygienic paints.

The negative health ramifications from toxic petro-chemical, plastic based paints is becoming more widely recognised. Historically, the area of key interest from consumers was purely colour, with most not appreciating the ecological and health implications of this most basic of selection criterias.

Heavily polluting paint production processes, in addition to the highly negative impact in homes and offices of toxic fumes on Indoor Air Quality from solvents and VOC’s went unrecognized. After painting, are you aware that the VOC levels in your space can increase by up to 1000 times? Manufacturers did react to some of the most damaging issues of the past decades, by for example removing lead content and some of the worst offending VOC heavy products, as regulations tightened.

Heavily polluting paint production processes, in addition to the highly negative impact in homes and offices of toxic fumes on Indoor Air Quality from solvents and VOC’s went unrecognized. After painting, are you aware that the VOC levels in your space can increase by up to 1000 times? Manufacturers did react to some of the most damaging issues of the past decades, by for example removing lead content and some of the worst offending VOC heavy products, as regulations tightened.

Recently however, events are forcing changed at a much faster pace. The widely publicised ecological crisis, so effectively documented by David Attenborough, Greta Thunburg and others, and now boosted by the recent Covid pandemic, are forcing much quicker developments.

Up until now, there was typically a compromise on performance in the selection of more ecological products. Also, many manufacturers have attempted to climb aboard the ‘eco-friendly’ marketing bandwagon. The majority of these brands have no genuine, independently verified certifications to support their claims which has resulted in an inevitable ‘green-washing’ backlash,… who can we trust?

Graphenstone have now secured more than 20 of the most recognised ‘harm-free’ certifications from the most eminent of product evaluation specialists globally. These include Cradle to Cradle (certified Gold and Silver), Eurofins (Indoor Air Comfort Gold), Ecolabel and many others.

Graphenstone have now secured more than 20 of the most recognised ‘harm-free’ certifications from the most eminent of product evaluation specialists globally. These include Cradle to Cradle (certified Gold and Silver), Eurofins (Indoor Air Comfort Gold), Ecolabel and many others.

Cradle to Cradle Institute for example dig deep into all aspects of your product, for example down to 100 parts per million in respect to ingredients, the sourcing of materials, the efficiency and renewability of water and energy use in production, local social responsibility, as well as how the products die out; it’s a thorough, demanding and expensive process.

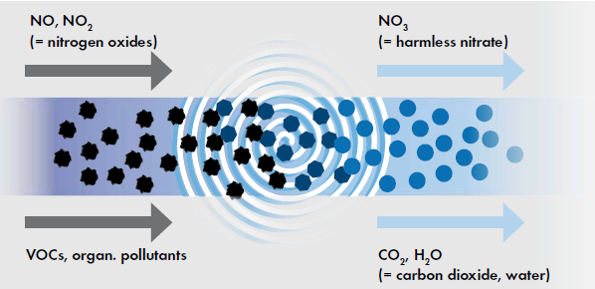

Graphenstone’s paints are also BREEAM, WELL, and LEED compliant and benefit from EPDs (European Product Declarations). The firm has developed a unique profile in the paints market. The range has no toxicity. In fact these products actively CLEAN and PURIFY the air, the pure lime based ranges removing CO2, SOx, NOx and other pollutants. What a total 180 degree turnaround from the polluting, toxic plastic based paints so widely specified in recent history.

Highly breathable, anti-bacterial (inhibiting all micro-organisms), Fire-proof (A1 EU, Class ‘0’ UK), Vegan, VOC free, Class 1 strength and in a range of over 1000 colours, we’ve created a beautiful matt lime based paint reinforced by graphene technology, a form of carbon which is the strongest material on earth. With no smell as well as quick drying, these paints contain no chemicals, plastic, microbeads, solvents or preservatives, with no traces of MIT or BIT. They are the Kings of Healthy and Sustainable paints.

Highly breathable, anti-bacterial (inhibiting all micro-organisms), Fire-proof (A1 EU, Class ‘0’ UK), Vegan, VOC free, Class 1 strength and in a range of over 1000 colours, we’ve created a beautiful matt lime based paint reinforced by graphene technology, a form of carbon which is the strongest material on earth. With no smell as well as quick drying, these paints contain no chemicals, plastic, microbeads, solvents or preservatives, with no traces of MIT or BIT. They are the Kings of Healthy and Sustainable paints.

To make the sustainable, environmental claim, the regularity of painting is crucial. Consequently, strength is a fundamentally important asset in more ways than one. Mineral products wouldn’t normally compete in respect to durability and life-cycle with synthetic-binder based paints (such as vinyl or acrylic). And this would typically result in a negative footprint ecologically, given the requirement for more regular repainting. However, via the introduction of graphene technology, providing structural support at the molecular level to the minerals, Graphenstone’s range offer Class 1 strength like an acrylic. But with none of the negatives in production or application, ensuring clean air in homes and offices.

Once applied, our paints could stay on your wall in a healthy and sustainable condition, for decades!

The Graphenstone pure limes can absorb up to 5.5Kg’s of CO2 per 15 litre pot! This offers the genuine concept of converting your walls into a natural air-purification system! Acrylic, VOC heavy options offer only a constant emitter of toxic fumes, impacting on the health and respiratory systems of all those living in these spaces. Graphenstone’s option can be compared to ‘painting trees’ into your house or office!

The Graphenstone pure limes can absorb up to 5.5Kg’s of CO2 per 15 litre pot! This offers the genuine concept of converting your walls into a natural air-purification system! Acrylic, VOC heavy options offer only a constant emitter of toxic fumes, impacting on the health and respiratory systems of all those living in these spaces. Graphenstone’s option can be compared to ‘painting trees’ into your house or office!

In conclusion, our message to designers is to carefully evaluate what product you specify. Is it genuinely in the interests of the people who’s lives will be impacted by that selection. Also, it’s a fundamental requirement now to check that the claims made by those brands you choose to work with can be independently verified and that the impact of your final decision is truly ‘harm-free’ for both, Nature, People and the Environment.

The future of clean, durable, advanced and sustainable paints is in fact available today.

Visit the Eurocell website

Visit the Eurocell website