View the Radmat entry on BPindex

This is a question worthy of the QI TV show, and one that would definitely get Alan Davies the famous Klaxon and flashing lights because the obvious answers of yes or no would both be incorrect.

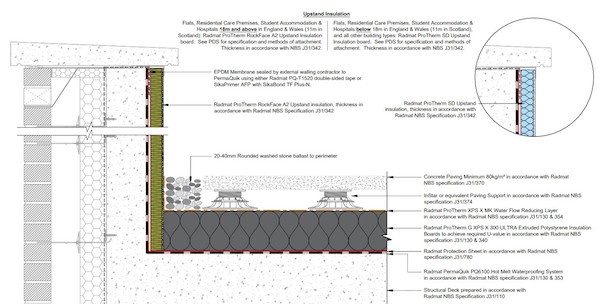

At present, based on the current wording in Approved Document B fire safety, the only clear YES answer is where the roof upstand is against habitable space ‘on a relevant building’, then you must use non-combustible insulation. Whether non-combustible insulation is required for parapet walls, rooflight kerbs, upstands etc. is not clear in Approved Document B fire safety, and is one area where it is hoped that the long-awaited response to the Ministry of Housing Communities & Local Government (MHCLG) consultation on Regulation 7 will provide clarity.

At present, based on the current wording in Approved Document B fire safety, the only clear YES answer is where the roof upstand is against habitable space ‘on a relevant building’, then you must use non-combustible insulation. Whether non-combustible insulation is required for parapet walls, rooflight kerbs, upstands etc. is not clear in Approved Document B fire safety, and is one area where it is hoped that the long-awaited response to the Ministry of Housing Communities & Local Government (MHCLG) consultation on Regulation 7 will provide clarity.

In the meantime, the major flat roofing industry Trade Associations have come together to produce a guidance document based on the understanding of the current regulations and the ‘direction of travel’ indicated by MHCLG. The guidance within the document is endorsed by the NHBC.

NFRC/LRWA/SPRA Guidance Document

This new document, published in mid-June 2021, clarifies that a combustible insulation board can be used on any flat roof upstand, but it:

- cannot extend more than 150mm above the roof finish/walking surface

- cannot be thicker than 60mm

- cannot span across a compartment wall line

- cannot be against habitable space

If any one of these requirements is not met then the insulation must be non-combustible i.e., suitable variants of FOAMGLAS or Rockwool that meet Reaction to Fire Class A1 or A2-s1, d0 to BS EN 13501-1.

The Guidance Document also highlights that all upstands on balconies (‘waterproofing’ over air rather than over heated space) are classified as part of a ‘Specified attachment’, and therefore all upstand insulation board must be non-combustible.

The Guidance Document also highlights that all upstands on balconies (‘waterproofing’ over air rather than over heated space) are classified as part of a ‘Specified attachment’, and therefore all upstand insulation board must be non-combustible.

But how will this knowledge transfer to the real world of on-site construction, or the purchasing office? Will the installers be provided with the knowledge to understand where they can use combustible insulation and where they cannot? Will they know where the compartment wall lines are when waterproofing a roof or terrace?

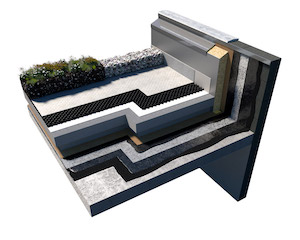

Whilst you can use combustible insulation within the legal requirements of Approved Document B, wouldn’t it be simpler to standardise all your flat roof specifications so that all the upstand insulation is non-combustible? This would avoid any confusion on site, avoid any risk of error and avoid any risk of having to pay for the removal and replacement of the incorrect insulation board.

Also, don’t forget to specify the vertical insulation from deck/vcl level upwards so as to provide a fire break between the combustible insulation running across the roof and the external wall.

Download a copy of the NFRC/LRWA/SPRA Guidance Document here https://radmat.com/news/new-trade-association-fire-guidance/