View the EJOT entry on BPindex

Visit the EJOT website

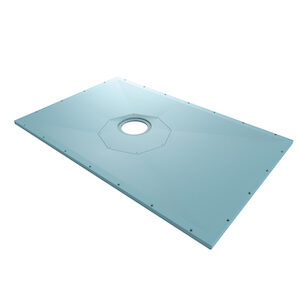

LIEBIG Superplus BLS offers versatility thanks to its modular design and range to suit numerous anchoring applications.

Whilst there is no one size fits all approach to concrete anchoring, by adopting a modular approach to anchor design EJOT has made it possible to use a single product for multiple different purposes on the same project.

The LIEBIG Superplus BLS is renowned across the world for its heavy duty performance capabilities. But for many engineers and specifiers, the anchor’s appeal is equally due to its versatility. Through a modular design, one product can be tailored and specified to meet multiple different applications ranging from garage equipment installation to mechanical and electrical supports.

LIEBIG Superplus BLS is ideal for anchoring of Industrial cranes and heavy machinery.

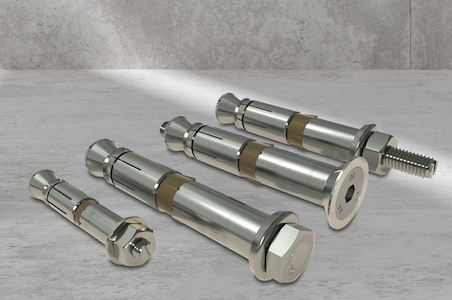

The key to the versatility of Superplus BLS is the ability to choose different variants of the core parts of the anchor. The length and diameter of the threaded bolt and the distance sleeve can be sized within a wide range and the head styles can be chosen to suit the specific application requirements.

It all adds up to an application-specific anchoring solution that can be configured in a way that is normally associated only with 100% bespoke anchors, which are notoriously costly in small volumes and incur long lead times. From a “kN per £” perspective, this makes Superplus BLS amongst the most competitive concrete anchoring solutions available.

EJOT’s ability to provide this level of versatility with the Superplus BLS comes down to the way its UK manufacturing facility is set-up. LIEBIG anchors are assembled at its UK’s factory near Leeds, where production is designed with agility in mind to accommodate different volumes of anchors to meet customer needs at relatively short notice. And for UK customers, the additional benefit of local supply means less risk of international transport delays.

The design allows for its core elements, the threaded bolt and the distance sleeve, to be sized within a wide range and the head styles can be chosen to suit the specific application requirements.

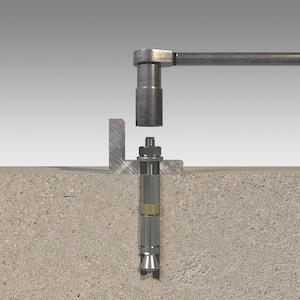

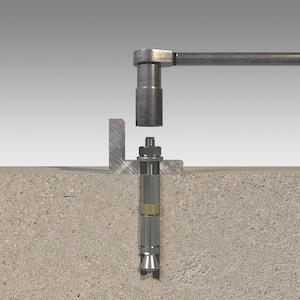

A consistent modular design applies to all Superplus anchors in the range, as well as offering the platform for ‘specials’. Whichever option is chosen, they all feature the innovative self-undercutting cone with teeth to create the undercut as it is drawn upwards when torque is applied during installation. No special tools are needed for creating the undercut, which speeds up the fitting process and reduces the potential for errors.

The core Superplus BLS anchor consists of a threaded rod with integral hex head. This is designed for through-fix post-installed application scenarios where installation is through the in-situ baseplate. This suits many different applications extremely well, especially given that the product is available in Grade 8.8 carbon steel, zinc plated, or A4-80 stainless steel for additional corrosion-resistance.

Beyond the standard Superplus BLS options, the product’s versatility is further demonstrated in some of the recent ‘special variants’ created by EJOT. These include the LPA (Lightning Protection Anchor) where rebar is known to attract and transmit an electric current flow through as a means to direct the current to earth.

This high level of versatility, coupled with superior anchoring performance, ease of installation and flexibility to accommodate site circumstances, makes Superplus BLS a solution that fits with the construction industry’s ambitions to build more efficiently and to ever higher standards.

Find out more at https://www.ejot.co.uk/LIEBIG_BLS.

We are thrilled to have been involved in this project at the award winning Eco Village in St Fagans, Cardiff with our BBA approved Addaset resin bound permeable surfacing system.

We are thrilled to have been involved in this project at the award winning Eco Village in St Fagans, Cardiff with our BBA approved Addaset resin bound permeable surfacing system. The Welsh Housing Minister Rebecca Evans visited the homes and commented:

The Welsh Housing Minister Rebecca Evans visited the homes and commented: