View the National Domelight Company entry on BPindex

Visit the Rooflights and Skylights website

Whether for maintaining solar panels, servicing rooftop building services plant, or providing access to roof terraces and gardens, every project must ensure that occupants and maintenance teams can reach the roof safely and with ease. Access hatches deliver a permanent, compliant, and secure means of access from within the building – eliminating the risks and inconvenience of external ladders or scaffolding.

Whether for maintaining solar panels, servicing rooftop building services plant, or providing access to roof terraces and gardens, every project must ensure that occupants and maintenance teams can reach the roof safely and with ease. Access hatches deliver a permanent, compliant, and secure means of access from within the building – eliminating the risks and inconvenience of external ladders or scaffolding.

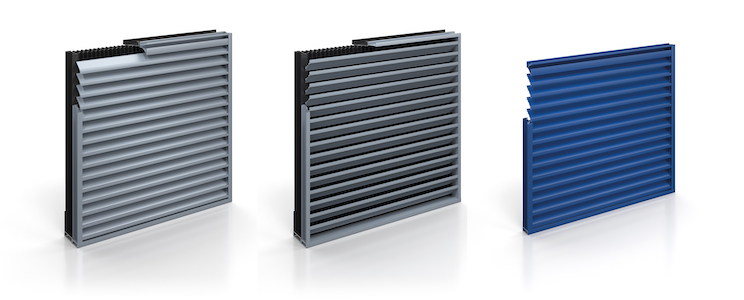

And while primarily a safety-critical feature, the right roof access solution can also enhance a building’s appearance. With modern flat glass and dome designs available, today’s systems combine robust performance with clean, contemporary aesthetics, ensuring safety never compromises style.

Rooflights & Skylights supply a comprehensive range of roof access hatches from leading UK manufacturers, helping specifiers match the right product to every application – from residential maintenance to high-traffic commercial use.

For occasional residential access, the Coxdome Trade Range Rooftop Access Rooflight provides a practical and economical solution for routine maintenance.

For more frequent access, such as entry to roof terraces and roof gardens or retrofit installations, options include:

- For compact, easy roof exit: the Coxdome Rooftop Entrance Rooflight features a vertical kerb design and sizes from as small as 600mm x 600mm.

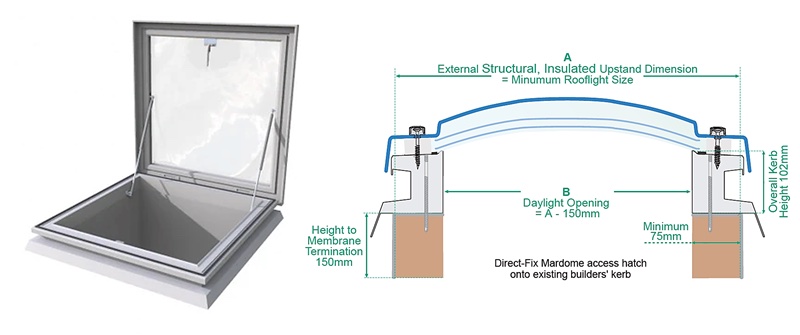

- For refurbishment projects with an existing timber kerb: choose the Mardome Access Hatch, ideal for reusing existing upstands.

- For combined ventilation and access requirements: the Coxdome Manual Vent & Access Rooflightprovides controllable ventilation and secure roof entry.

- For direct-to-deck installations: the Thermadome Access Hatch includes an insulated PVC kerb for straightforward fitting.

- For contemporary aesthetics and effortless operation: the Brett Martin Flat Glass Access Hatch offers electric opening at the touch of a button.

For commercial applications, the Thermadome Commercial Access Hatch offers a durable aluminium construction and high-performance insulation – ideal for plant maintenance and service access.

For commercial applications, the Thermadome Commercial Access Hatch offers a durable aluminium construction and high-performance insulation – ideal for plant maintenance and service access.

Visit the Rooflights and Skylights website available from Rooflights & Skylights – your trusted partner for daylighting and roof access solutions.