View the Howe Green entry on BPindex

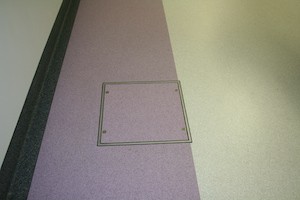

For demanding public sector environments that experience significant levels of pedestrian footfall, the correct specification of permanent floor access solutions is vital to not only providing secure and maintenance-free access to underground services, but also ensuring the highest levels of hygiene and safety at all times.

Here Chris George, Business Development Manager at Howe Green, explores the latest floor access solutions available to specifiers and architects to meet a diverse criteria of requirements.

For professionals working on renovation or new build projects within the education, healthcare and high-end hospitality sectors, there are a breadth of varying specifications that must be addressed at the design stages to ensure the long term suitability and compliance of the building components installed.

For professionals working on renovation or new build projects within the education, healthcare and high-end hospitality sectors, there are a breadth of varying specifications that must be addressed at the design stages to ensure the long term suitability and compliance of the building components installed.

With regard to floor access covers in particular, durability and functionality are two of the first areas that must be considered. This includes assessing whether the materials used to construct the access cover can withstand the high frequency of pedestrian footfall and the subsequent weight loading requirement for the chosen environment.

Lightweight aluminium floor access covers offer both resilience and ease of use, whilst also being resistant to corrosion, a key requirement for the healthcare and education sectors due to the high level of cleaning and sanitisation required.

Lightweight aluminium floor access covers offer both resilience and ease of use, whilst also being resistant to corrosion, a key requirement for the healthcare and education sectors due to the high level of cleaning and sanitisation required.

Compatibility with a wide range of flooring materials is also an important part of this stage of the specification process. Here professionals should look to specify solutions that are suitable for installation with all types of flexible floor finishes, including vinyl, linoleum, rubber and carpet.

The prevention of dirt and water ingress should also be considered to maintain the highest levels of hygiene. Here it’s recommended to explore access covers that have been specifically designed to bond and weld the sheet flooring to create an impermeable, flat and permanent joint.

Once the above criteria have been met, specifiers should then address the initial installation process, ease of use and ongoing maintenance of the floor access covers.

Once the above criteria have been met, specifiers should then address the initial installation process, ease of use and ongoing maintenance of the floor access covers.

Due to their light weight, aluminium covers can be extremely versatile as they support quick and easy installation, which also delivering an accurate and unobtrusive finish that doesn’t require continuous upkeep.

The process of gaining access to underground services can also be streamlined through the use of lifting keys, which safely and securely raise the access cover to minimise any on-site disruption and also ensure compliance with all relevant health and safety guidance.

Finally, working with a manufacturer that supports bespoke specifications will also ensure each specific requirement is successfully met. This includes cover sizes, configuration of ducts and branches, along with various weight loadings.

Howe Green’s unique Visedge® Series is regularly specified for high profile healthcare developments including Queens Hospital, Romford, and Southmead Hospital, Bristol, whilst also being the access solution of choice for leading educational institutions including The University of Surrey and John Moores University, Liverpool.

The resilient floor access covers are the ideal choice for challenging healthcare, hospitality and educational environments due to the innovative double top edge seal construction, which provides the highest standards in hygiene and safety.

The VisedgeⓇ Series is manufactured to BS EN ISO 9001:2015 at Howe Green’s headquarters in Hertfordshire using CAD and C.N.C machinery.

For further information on the Visedge Series and Howe Green’s complete range of floor access solutions, visit www.howegreen.com or call 01920 463230.