View the MMA Architectural Systems entry on BPindex

Visit the MMA Architectural Systems website

Visit the MMA Green walls website

Against the backdrop of a growing global population, the rise of mega-cities and the impact of climate change, greening our towns and cities has become increasingly important, to make sure that our urban environments are safe and healthy places to live, work and study in, and to visit. So, what are the benefits of Jakob’s Green Wall solutions for these applications?

Against the backdrop of a growing global population, the rise of mega-cities and the impact of climate change, greening our towns and cities has become increasingly important, to make sure that our urban environments are safe and healthy places to live, work and study in, and to visit. So, what are the benefits of Jakob’s Green Wall solutions for these applications?

Green Walls continue to play a crucial role in delivering sustainable urban landscapes, with designers and architects recognising their versatility and value both for cladding facades and as stand-alone structures. Jakob Green Walls have been proven to deliver a wide range of benefits for both new build projects and retrofit/ refurbishment schemes, including:

- Energy savings and reduced carbon footprint – energy savings up to 35% can be achieved due to the effects of evaporative cooling and shading by plants, leading to a much lower carbon footprint.

- Noise reduction – thanks to the exterior sound reflection and absorption, noise can be reduced by up to 5 dB.

- Improved air quality and CO2 balance.

- Enhancing a building’s appearance.

- Encouraging biodiversity – bringing flora and fauna back to our urban environments.

- Cost-effective solution – compared to hydroponic pocket systems.

- Suitable for new projects or retrofitting to existing buildings.

- Easily installed and maintained.

When they are installed on buildings or in public spaces, Jakob Green Walls (also called Living Walls) deliver much more than an attractive environment. In addition to enhanced aesthetics, they bring flora and fauna back to our towns and cities, creating sustainable natural habitats in urban spaces for a variety of plants and insects. The reductions in noise and improvements to air quality they bring also help to improve the health and well-being of people living and working in, or visiting a city.

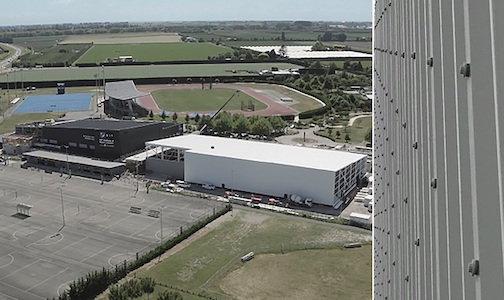

The technology behind Green Walls is developing quickly, with systems constantly evolving and new projects bringing innovative solutions and applications. The scale of projects is also increasing, with One Central Park in Sydney being a soaring example: this 150 metre high building is home to the world’s tallest exterior Green Wall, the Jakob Green Wall system having been supplied by our Australian partners, Tensile Design & Construct.

The technology behind Green Walls is developing quickly, with systems constantly evolving and new projects bringing innovative solutions and applications. The scale of projects is also increasing, with One Central Park in Sydney being a soaring example: this 150 metre high building is home to the world’s tallest exterior Green Wall, the Jakob Green Wall system having been supplied by our Australian partners, Tensile Design & Construct.

Spanning 120 square meters across two residential towers, the system was developed with support from Jakob Green Solutions, with the vertical surfaces containing 35,200 plants to provide both shading and cooling for the building’s interior in the hot Australian climate.

Green Walls do not just deliver outstanding performance for external projects. They can equally help transform internal spaces, with the single cable systems improving indoor climates by filtering and capturing particles and CO2 in exchange for oxygen – again dampening noise and adding a creative, sustainable, and inspiring living element to an interior space.

The Jakob Green Wall system has been specified in projects worldwide, providing a contemporary and elegant design aesthetic, whilst allowing a wide range of planting options to be installed to suit the local conditions and environment. Providing a modern, sustainable solution, Green Walls are increasingly being installed to bring nature back to our urban landscapes.

To learn more about our Jakob Green Wall Systems, or to discuss your project requirements, please contact us on 01761 419427 or email sales@mma-architecturalco.uk to talk to our technical team.